ball nose end mill feeds and speeds

0005 for a 18 end mill up to. Using the same criteria as the spindle speed calculation RPM 6037.

Amazon Com Wokesi 1mm 1 5mm 2mm 3mm Cutter Dia Pack Of 4 Std Length 4flutes Hrc55 Tialn Coated Metric Solid Carbide Square Nose End Mill Cnc Router Bits Cutting Milling Tools 1mm 1 5mm 2mm 3mm Hrc55 Industrial Scientific

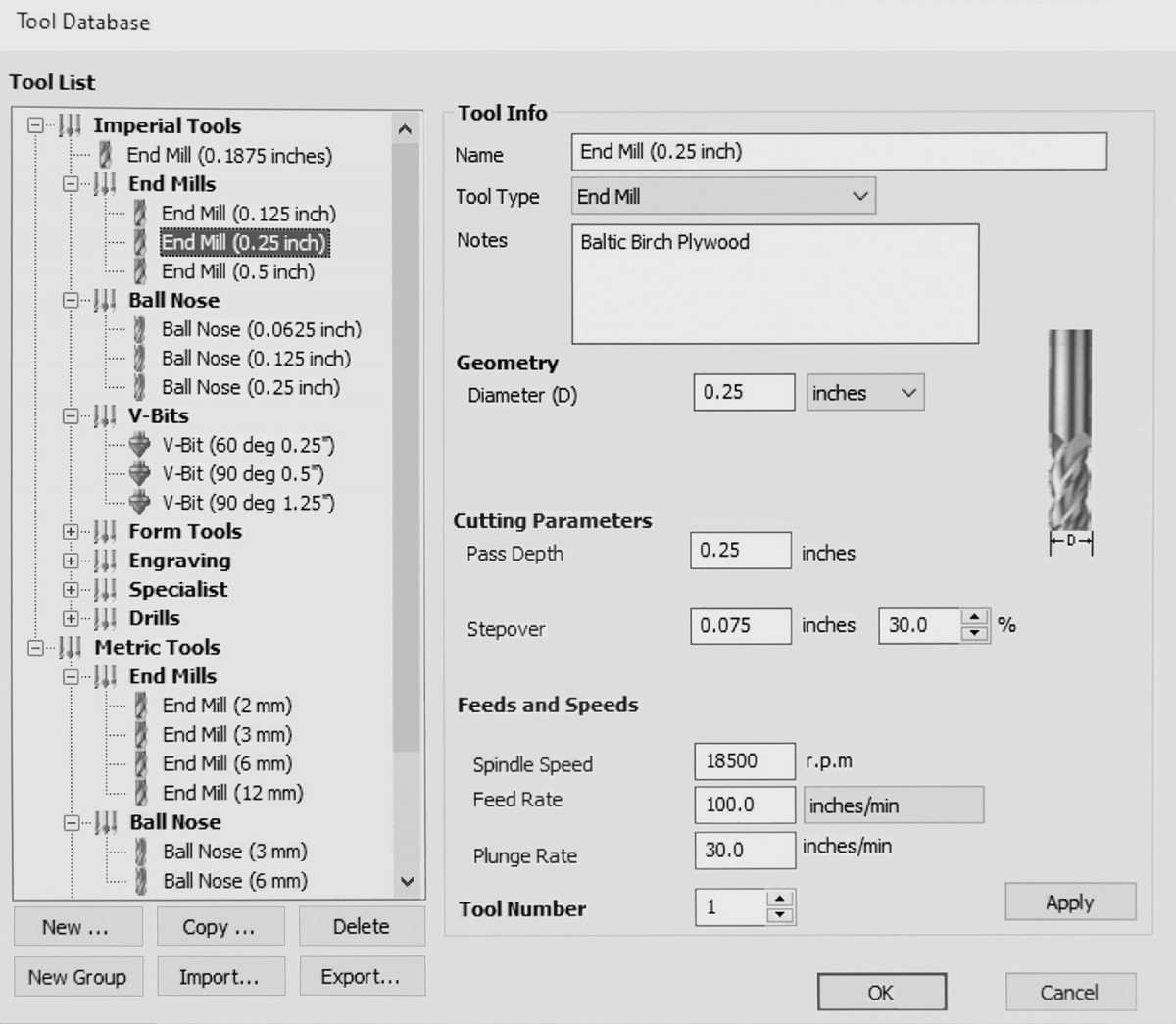

The calculator will automatically provide the necessary speed and feed in the green fields.

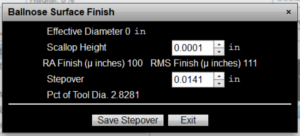

. Corner Radius Corner radius end mills feature a radius at the corner edge of the mill. Ball nose tip provides step-free contour milling of 3D solid models. The effective cutting diameter will be used to make both speed and feed adjustments.

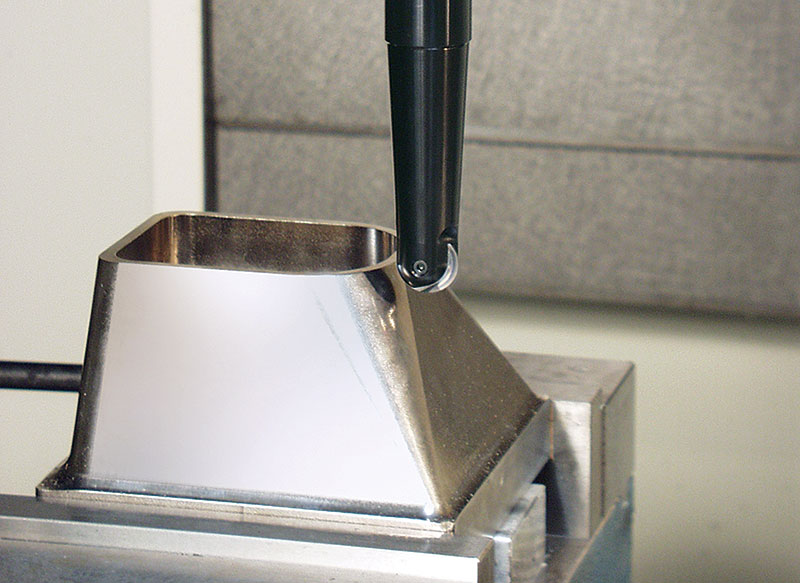

The parameters provided are suggested operating parameters. Designed for high speed roughing and finishing of complex contoured shapes in hardened materials. Cutting edge geometry virtually eliminates chatter at high feed rates.

Speeds Feeds Library. The full radius or ball shape permits high accuracy contouring and profiling. Speed Feed - General Purpose End Mills - Melin Tool Company Melin Tool Company speed feed recommendations for high performance end mills.

Spiral geometry insures efficient debris removal. Ball Nose Milling Without a Tilt Angle. Their tapered profiles make them much stronger than.

All posted parameters are suggested starting values that. MB Ball Nose Insert Unique cutting edge allows performance in all operations in material below 42. Doesnt really matter the speeds and feeds.

Below you will find downloadable and printer-friendly Speeds Feeds for each one of our products. Ball nose end mills are ideal for machining 3-dimensional contour shapes typically found in the mold and die industry the. Excellent choice for unattended finish milling at small depth and high speeds and feed rates.

When machining stainless steels it is generally advised to use an SFM of between 100 and 350 and the chip load should range from. Home Products Find a Distributor. The Turbo Carb end mill is made of an application specific carbide to improve wear.

Radial Side Depth of Cut This will adjust the feedrate if less. 006 for a 1. Ball End Mills Ball nose end mills featuring a full radius are ideally suited for milling 3-D contoured parts.

End Mill Speed and Feed Calculator - Martin Chick Associates Contact End Mill Speed Feed Calculator Tool Dia. Calculate effective diameter The thing about a ball nose if if your cut depth. Materials Tapered ball-nose end-mills are the most commonly used cutters for deep CNC carving in wood plastic and metal.

Fill in the blocks shaded in blue with your application information. Ball nose end mills featuring a full radius are ideally suited for milling 3-D contoured parts. But here is a simplified version of the formulas to use if you want to calculate ball nose speeds and feeds.

Ie- 6037 x 0005 x 2. From the chart chip thickness is 0005 and all of our ball nose finishers have 2 flutes. Determine the effective cutting diameter De of the end mill based on the axial depth of cut.

We have listed these also as individual recommendations. Certain high performance end mills have very specificc running parameters relative to their material families. Actual speeds and feeds will depend on many variables such as rigidity workpiece hardness tool extension machine.

In Oak - which is a really course grained wood - bits that small will not really yield anything that fine in detail any way - even if. Adjust speedsfeeds and width of cut to pull enough heat in chip. With advanced technologies and facilities strict good quality manage reasonable rate superior assistance and close co-operation with shoppers we have been devoted to supplying the very.

Chips should maintain color blue purple etc Always use caution and best judgement when applying updated.

Highly Efficient Fxs Carbide Ball Nose End Mills Vol 3

China Carbide Ball Nose End Mill Speeds And Feeds Manufacturers And Factory Suppliers Msk

Yg 1 Best Value In The World Of Cutting Tools

How To Calculate Speeds And Feeds Metric Version Haas Automation Tip Of The Day Youtube

Solid Carbide 2 Flute Tapered Ball End Mills Sdk Tool Supply

Feeds Speeds For Cnc Routers Popular Woodworking

Gm 4bl R6 0 R7 0 Cemented Carbide Higher Feed Speed Machining Efficiency 4 Flute Ball Nose End Mills With Straight Shank Tools End Mills Ball Nose End Millsball Nose Aliexpress

Spetool Tapered Ball Nose End Mill 1 4 Shank With 1 16 Cutting Radius 1 8 Diameter For 3d Carving Engraving Router Bit Zrn Coated Amazon Com Industrial Scientific

Maximizing Mrr With Tools For High Speed Milling

Harvi I Te Ball Nose End Mill Cutting Tool Engineering

Ball Nose End Mill Easy Guide To Ball Cutters Cnccookbook Be A Better Cnc Er

Best End Mills For Cnc Machine M3tools

End Mill Sizes Chart Of Inch Metric And Micro Diameters

Ball Nose Finish Milling Reference Troubleshooting Info Dapra Corporation

Speed Feed Recs Melin Tool Company

End Mills The Essential Beginners Guide

Recommended Cutting Conditions Ball Technical Information Tools For Machine Processing Tools Misumi Vona Comprehensive Web Catalog For Misumi

Ball Nose End Mill Easy Guide To Ball Cutters Cnccookbook Be A Better Cnc Er

Astra Coated 1 8 Up Cut Ball Nose Cnc Router Bit Bitsbits Com